DHT-250 is result of our commitment to give economical, fully calibrated solution in quality assurance for tablet testing.

DHT-250 advanced microprocessor control, accuracy and versatility are now together in one instrument and capable to measure thickness, diameter and hardness.

DHT-150 uses an load cell with strain measuring gauge with micro controller Based circuit to give accurate results & quick response. The stainless steel test jaw is driven by stepper motor. Calibration kit & software specially developed to calibrate this unit by customer himself. The linearity of system can also be checked by using weight & using verify mode.

The tablets are placed manually, one after the other, into the test zone of the instrument. The top-loading jaw design accommodates any shape and size of the tablet with out changing any alternative / additional jaws.

Campbell Electronics has launched new Tablet Dissolution System DRS-Series represents the very latest in tablet testing technology. Excellent production techniques combined with modern microprocessor design guarantee the highest standards of performance and reliability. All dissolution testers meets the latest specifications as laid down in the European, United States and associated pharmacopoeia.

Campbell Electronics has launched new Tablet Dissolution System DRS-Series represents the very latest in tablet testing technology. Excellent production techniques combined with modern microprocessor design guarantee the highest standards of performance and reliability. All dissolution testers meets the latest specifications as laid down in the European, United States and associated pharmacopoeia.

Programmable Recipes :

Up to 50 recipes can be created, stored and recalled for running the test with that particular recipe any time. In each recipe user can enter the particulars of number of steps, step duration, sample volume, sample interval, product information etc.

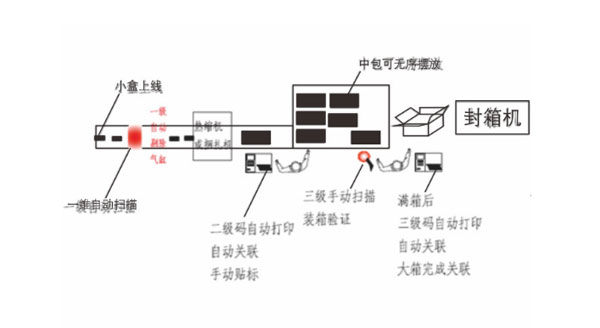

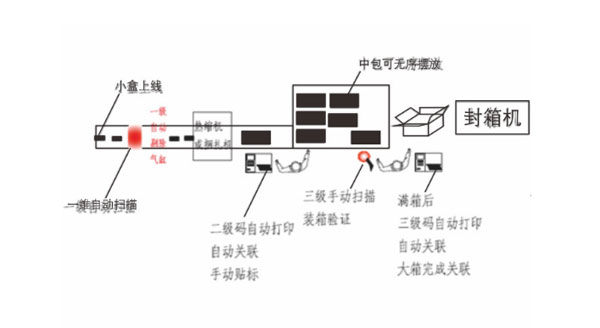

Under the CFDA (China Food and Drug Administration) electronic system for supervising and administering production and distribution of all types of pharmaceutical products, each package of a drug product must be identified by a unique electronic supervision and administration code (the “Code“). The Code is composed of a 20-digit number, a bar code and text (such as telephone number and website address).

The Code must be indicated on the exterior of the package itself and identifies basic information such as drug name, manufacturer, approval number, dosage form and strength, date of production, batch number and package size. All drug manufacturers and distributors are required to record the flow path of a drug product from when it is packed until it reaches the end user or medical institution in a centralized national database maintained by CFDA.

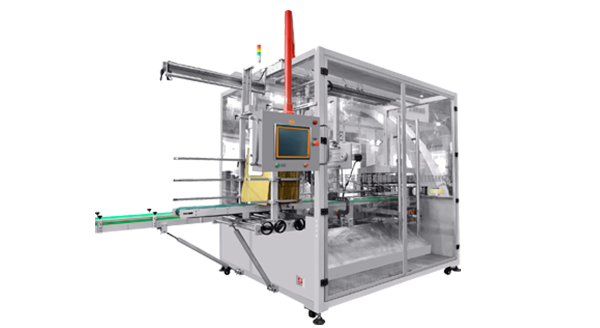

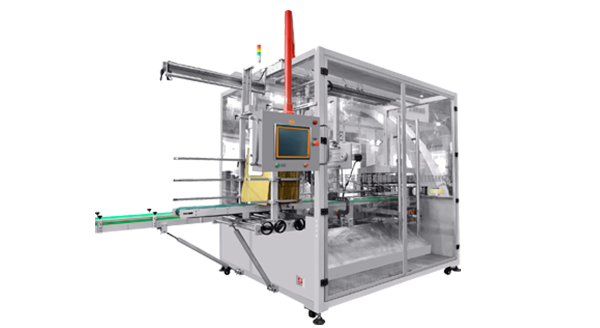

On the basis of combining features of various boxing machines at home and abroad, to meet the features of domestic manufacturers, we have successfully researched and developed the latest automatic integrated boxing machine(unpacking, boxing and sealing), which can be used individually with a wide application range and small floor space. It is suitable for automatic boxing of boxed products of various specifications, and can also work with baling, three-dimensional, heat shrinkage equipment and etc. at front procedures. The machine is widely applied in such industries as pharmacy, food, daily chemical industry and other light industries.

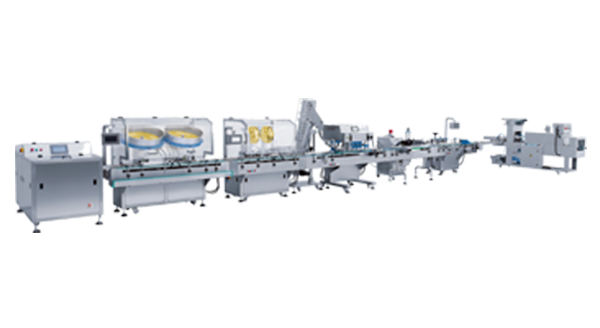

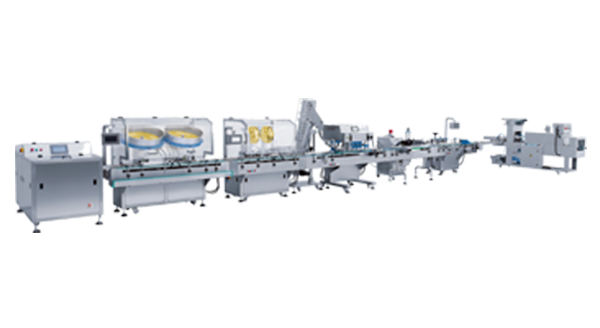

The automatic bottle packaging production line is composed of bottle unscrambling and tablet counting machine, paper inserting machine, aluminum foil sealing machine, adhesive labeling machine, and etc. The production line offered by Xin Weisheng is suitable for various forms of tablets, such as round tablets, ball tablets, soft and hard capsules, and etc. It can complete the whole process including empty bottle feeding, material counting, filling and packaging of finished products. It can effectively reduce labor intensity of operators and enhance productivity and product standardization.

With an integral tunnel structure, the machine includes three parts: the preheating area, high temperature sterilizing area and cooling area. It adopts the hot air laminar flow disinfection principle to carry out instant high temperature sterilization of the vessel. It is suitable for drying and sterilization of ampoules, antibiotic bottles, oral liquid bottles and other medicinal glass bottles. The machine adopts the advanced PLC man-machine interface control system. Through the man-machine interface control, the operating status of the machine is monitored and the requirements for production processes are met, while the combined control of the operating status for both the cleaning and filling equipments can also be realized to display the fault causes, locations, simple eliminating methods, and etc. In addition, temperature and curves can be recorded automatically.

The machine is suitable for high-precision filling of ampoules and vials, as well as filling and sealing of ampoules, and automatic stoppling or semi-stoppling of vials. It adopts PLC control, integrates advanced intelligent electric control technology and visualized man-machine interface, and realizes the perfect design of mechanical and electrical integration. The machine is provided with the functions of no filling in case of no bottle and no stoppling in case of no bottle. The surfaces are made of high quality 304 stainless steel, conforming to GMP requirements.

The aseptic transfer cabinet is used for biological dirt removal treatment on the exterior surface of materials, so as to prevent materials from entering class A/B key regions from no-class regions/low-class clean regions. Taking advantage of hydrogen peroxide in the gas state at normal temperature having better ability to kill microorganisms than that in the liquid state, the saturated hydrogen peroxide vapor forms slight cold condensation coating on the material surface that releases free hydroxyl groups, which is used to attack microbial cell components including lipids, proteins and DNA so as to meet the requirements of complete inactivation of microorganisms. The machine can be used for various clean and dry objects that need to be transmitted during aseptic production, for example, external packaging of packing materials, instruments, vessels, packing of raw and auxiliary materials, fittings, environmental monitoring equipment, and etc.

With a vertical rotary drum structure, the machine adopts mechanical hands to clamp and turn bottles, whilst the spray tube carries out the reciprocating tracking process. Taking advantage of the ultrasonic washing and water & gas alternating jetting washing, the whole automatic production process includes bottle feeding, ultrasonic washing, external washing, internal washing and bottle discharging. The overall transfer process simulates the gear external engagement principle.The machine has features such as low bottles’ breakage rate, good adaptability and stable running while there is no cross contamination of water and gas pipes, so the machine fully meets the GMP requirements.