The ALXI-III model ampoule washing-drying-filling-sealing production line is composed of the QCL series vertical ultrasonic bottle washing machine, ASMR tunnel hot air circulation sterilizing oven and AGF series vertical filling-sealing machine, whilst the three component machines can also be used independently. Suitable for production of ampoules of 1-20ml, it can complete more than 20 pharmaceutical procedures such as spray and water filling, ultrasonic rough washing, bottle exterior wall washing, bottle interior wall continuous twice circulation water washing, primary blowing, primary fresh water washing, continuous twice blowing, bottle exterior wall blowing, preheating, drying, sterilizing, pyrogen removing, cooling, front gas charging, filling, rear gas charging, preheating, sealing, and etc. The production line is a new-type line which is researched and developed by us after years of efforts through integrating our proprietary patented technologies on the basis of digesting and absorbing advanced domestic and overseas technologies.

The whole line adopts PLC main control, frequency converter and touch screen control technology whilst the production process is stable and reliable. The touch screen can display running dynamics of each single machine, water pressure, air pressure, wind pressure and temperature at each control point. The display of each on-off status and faults, fault self-diagnosis, fault analysis and eliminating methods realizes automatic control during the whole production. The production line is provided with the three-machine automatically control and balancing device to ensure the balanced and reliable production.

The oral liquid washing-drying-filling-capping production line is composed of the QCL series vertical ultrasonic bottle washing machine, ASMR tunnel hot air circulation sterilizing oven and YGZ series oral liquid filling-capping machine. Suitable for production of oral liquid bottles of 2-25ml, it can complete such procedures as water spray, ultrasonic washing, water filling, gas charging, drying, sterilizing, cooling, filling, capping, and etc.

The full automatic ampoule injection impurity detecting machine is mainly used for automatic detection of visible impurities and seal faults of small volume injections, oral liquid bottles in pharmaceutical enterprises. With advanced and compact design, the machine adopts high resolution industrial cameras for multiple camera shooting detection of the liquids, so that the visible impurities that may exist in transparent or semi-transparent liquids can be recognized and detected fast and accurately (such as glass shards, scrap metal, fiber, white spots, white blocks, and etc.,). The machine can also accurately judge if the filling volume is within the permissible range. In addition, the ampoule injection lamp inspection machine can carry out inspection of oral liquid bottle caps. The nonconforming products can be directly separated from the dialing wheel without entering the detection wheel disc, so that the inspection speed and precision can be greatly enhanced to meet the stipulations in the Chinese Pharmacopoeia.

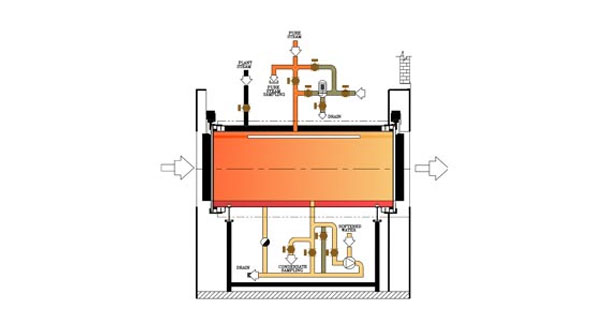

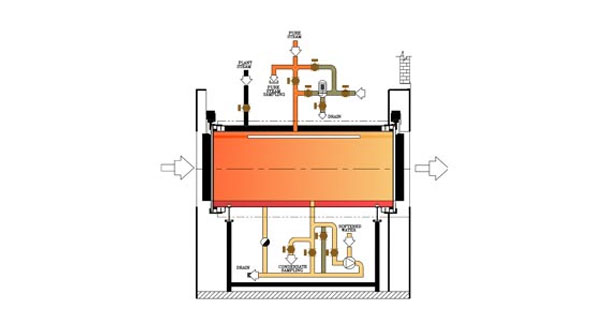

The production programs in the pharmaceutical industry are aimed at maximum safety, top quality and high economy. This applies in particular to the sterilization process. Steam Sterilizer continues to be one of the ancient but widely used sterilization techniques in the Life-Science & HealthCare Industry. The process systems now have to meet the most exacting demands for temperature and pressure / Vacuum control and process documentation. A sterilization systems represents Therefore, Machinfabrik takes measures to ensure that our Sterilizers provide and life cycle economy. Every Sterilizer is produced to your specifications and needs. Flexible options allow selection of the right equipment for each specific sterilization load and packaging.

The Vertical Autoclave is effective for Sterilization and Decontamination in a Laboratory, Research Center or Testing Facility. The system is designed to perform gravity displacement sterilization cycles and can be optionally fitted with a vacuum system to perform pre-vacuum sterilization cycles thereby offering maximum flexibility to the user. The system is controlled by a PLC and is provided with a user-friendly operator terminal. Wide range of options are available for batch documentation, which comply with the recent regulatory requirements.

Compliance with strict regulatory guidelines and quality requirement demands accurate measurement, secure data, comprehensive reporting and alarms notification unlike any other product.

NECLOG provides variety of physical parameter to be logged, reported and alarm notification. Temperature, Humidity, Differential pressure, CO2 etc.

Neclog is one of the unique solution with many advantages as easy-to-use, cost effective, high-accuracy solution for mapping critical and FDA-regulated environments form stability chambers to freezers and warehouses.

Simple configuration and connection of multiple sensors on serial link makes it easy to use and hassle free.

On line data on base unit and on PC allows to track performance in real time.

NECLOG maintains all data and events in secure files, providing temperproof security with presentation ready reports to meet 21CFR Part 11.

At Newtronic, We Introducing, A World class Spark free, Flame Proof Walk in Chambers, Flame proof chambers are needed for storage of aerosol, volatile, flammable liquids, reagents, chemicals and organic solvents, that meet class 1, Division 2 Criteria. These volatile substances are normally store in containers and in a controlled temperature chambers. We provide explosion proofing to all interior components of the chambers including light fittings, Motors, Control Panel, HMI, Sensors*. Our Flame proof chambers are optionally supported by FM200 Fire Suppression systems.

“Necessity” leads the way to creations and innovations. One such necessity was to create a contamination free pass way for the lab apparatus between clean room and grey room.

Newtronic presents to the pharma world, the Pass Through lab Oven. This oven comes with double door opening with interlocking facilities between the two doors.

These units are fitted with highly accurate controller that allows gentle drying of heat sensitive materials & highly hygroscopic materials.

The vacuum ovens can dry faster than the conventional ovens & avoid damage due to rapid temperature overshooting.

They come with a separate vacuum release valve to release the vacuum by gentle turn of the knob. An air release inlet is located below the tray to avoid sample disturbance due to air blowing.

These units are primarily used in applications which require rapid drying and sterilization. Totally homogenous temperature distribution, rapid dynamic response and a special air turbine developed by us which has higher output have made it a genuine time-saving device.

They are also used to measure the loss on drying & are also referred to as LOD Ovens or Hot Air Ovens.

Units are equipped with Stainless steel trays, high quality PT-100 sensor & a microprocessor based controlling system with 2 line alphanumerical LED display. Alarms are generated for any deviations. The PID controller comes with an integrated timer functionality from 0 to 99 hours for ramp & soak functionality.

Introduction: Shaking incubators, also known as environmental shakers, are often used for cell culturing, cell aeration, and solubility studies. In addition to stable temperature conditions, they use an orbital agitation at variable speeds to affect the growth of cell cultures. Newtronic Shaking Incubators have adjustable speed and orbit to meet each application. Models can equipped with a universal shaking platform, or fixed flasks. Independent alarms, and PLC based controls for temperature and speed adjustment with Touch screen display.